Infrared cameras PYROVIEW for industry and research

Thermal imaging cameras are used for non-contact temperature measurement and for the detection of twodimensional temperature distributions with high thermal resolution on stationary and moving measurement objects. We have introduced the longtime experience in the field of thermography into our thermal imaging camera series PYROVIEW. The devices are durable, robust and suitable for industrial continuous operation. Our infrared cameras are used in process control and monitoring, quality control, early fire detection as well as for measurements in research and development.

An extensive range of fixed thermal imaging cameras is available for our customers.

Everything at a glance: Overview brochure: models of fixed infrared cameras PYROVIEW

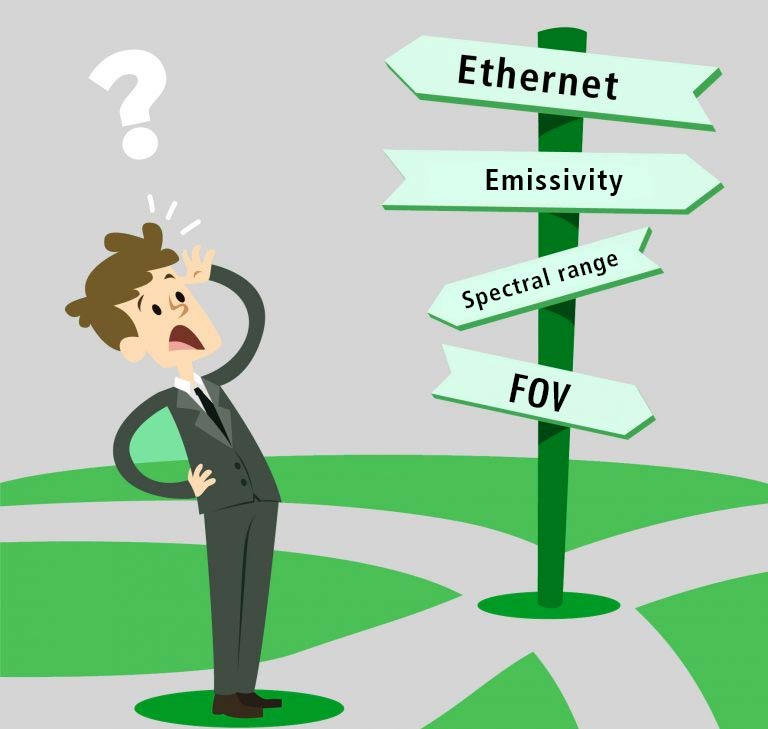

What spectral range should my infrared camera have?

Please note: To minimize temperature measurement errors resulting from emissivity inaccuracies, you should measure at a short wavelength. Please read this article for more information. Here is an overview of all offered spectral ranges, recommended temperature ranges and application examples of our thermal imaging cameras.

| Material | Temperature range | Spectral range | Shortcut |

|---|---|---|---|

| Non-metals, coated metals | -20 °C to 500 °C | 8 µm to 14 µm | “L” |

| Glass surfaces | 300 °C to 700 °C | 4.8 µm to 5.2 µm | “G” |

| Measurement through flames and combustion gases | 600 °C to 1250 °C | around 3.9 µm | “F” |

| Ceramics, metals | 200 °C to 500 °C | 3 µm to 5 µm | “M” |

| Metals, ceramics, graphite | 300 °C to 750 °C | 1.4 µm to 1.6 µm | “S” |

| Metals, glass melt | 600 °C to 3000 °C | 0.8 µm to 1.1 µm | “N” |

Which fixed infrared camera suits your requirements?

Depending on the application our fixed thermal imaging cameras are available with different thermal and spatial resolutions, spectral ranges and temperature ranges as well as with different housing variants. In addition there are numerous motor focus infrared lenses, including wide angle and tele photo lenses, for an optimal adjustment of the camera to different measurement objects and measurmeent object sizes at different measurement distances. Here is a overview of our fixed infrared camera models:

| Camera type | Pixels | Temperature range | Spectral range |

|---|---|---|---|

| PYROVIEW 380L | 384 x 288 | -20 °C to 120 °C and 50 °C to 500 °C | 8 µm to 14 µm |

| PYROVIEW 640L | 640 x 480 | -20 °C to 120 °C and 50 °C to 500 °C | 8 µm to 14 µm |

| PYROVIEW 640M | 640 x 480 | 200 °C to 500 °C | 3 µm to 5 µm |

| PYROVIEW 640G | 640 x 480 | 300 °C to 700 °C | 4.8 µm to 5.2 µm |

| PYROVIEW 640F | 640 x 480 | 600 °C to 1250 °C | about 3.9 µm |

| PYROVIEW 512S | 512 x 408 | 300 °C to 750 °C | 1.4 µm to 1.6 µm |

| PYROVIEW 512N | 512 x 384 | 600 °C to 1500 °C or 1400 °C to 3000 °C | 0.8 µm to 1.1 µm |

| PYROVIEW 768N | 768 x 576 | 600 °C to 1500 °C or 1400 °C to 3000 °C | 0.8 µm to 1.1 µm |

| PYROVIEW 1600N | 1600 x 1200 | 650 °C to 900 °C, 750 °C to 1100 °C, 850 °C to 1300 °C, 900 °C to 1400 °C, 950 °C to 1500 °C or 1100 °C to 1800 °C | 0.8 µm to 0.9 µm |

| PYROVIEW 1920N | 1920 x 1080 | 650 °C to 900 °C, 750 °C to 1100 °C, 850 °C to 1300 °C, 900 °C to 1400 °C, 950 °C to 1500 °C or 1100 °C to 1800 °C | 0.8 µm to 0.9 µm |

Fixed infrared cameras – housing variants

Infrared camera series PYROVIEW compact+

The industrial thermal imaging camera series PYROVIEW compact+ is a series for stationary use and the exact measurements of the temperature distributions in compact exterior dimensions. More about the thermal imaging camera series PYROVIEW compact+.

Infrared camera series PYROVIEW protection

In the housing version “protection” the camera is in an IP65-housing with air purge, water cooling and protection window, so that ambient temperatures up to 150 ° C are possible. Learn more about thermal imaging camera series PYROVIEW protection.

Special housings

Further housings are available for special application. Examples are ATEX housing and weatherproof housing, also with pan-tilt-head.

Numerous application areas

The application areas of our infrared cameras are very manifold. Everywhere where temperatures in the process play an important role our cameras can be integrated. Due to different housings, optics and complete system solutions complex measurement tasks can be solved. Our infrared cameras PYROVIEW are used in the following application areas for example:

- Quality management in steel industry, glass industry or cement production

- Process automation and process control: production of semiconductors or wafers for solar industry

- Research and development projects: nondestructive testing of materials, studies of aspects in veterinary medicine

- Early fire detection in storage buildings, forests and even in cities

- Traffic control in road tunnels

- Process control in metallurgy

- Inspection of electrical equipment

- Building thermography around thermal bridges and localization of weak points in wallings