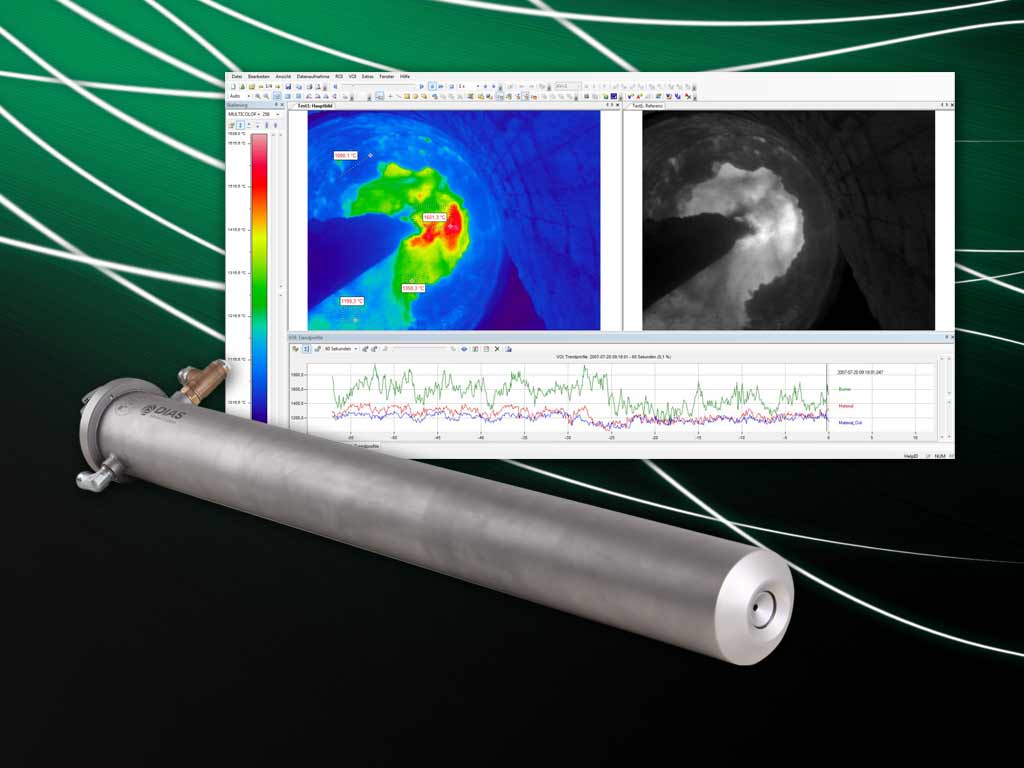

PYROINC – Temperature monitoring in combustion chambers with infrared cameras

Patented air purging system and cooled probe lens allow years of service life

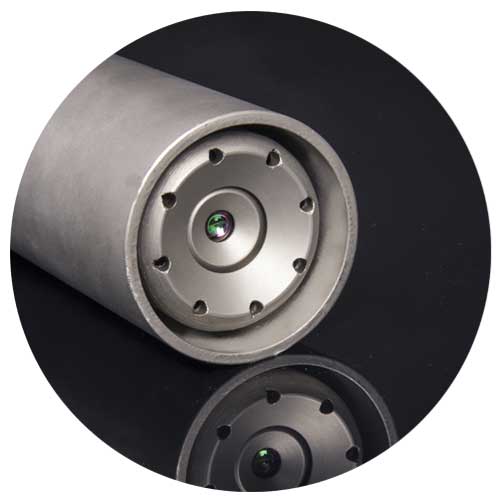

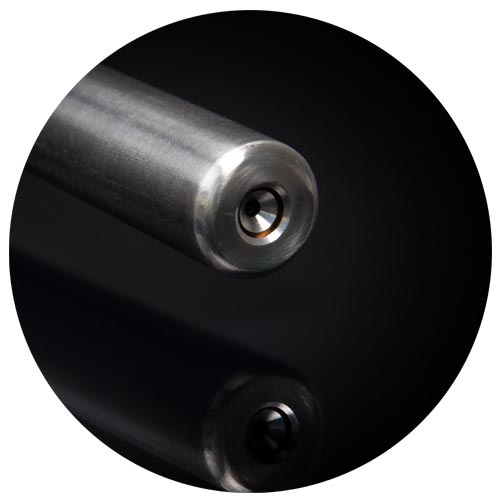

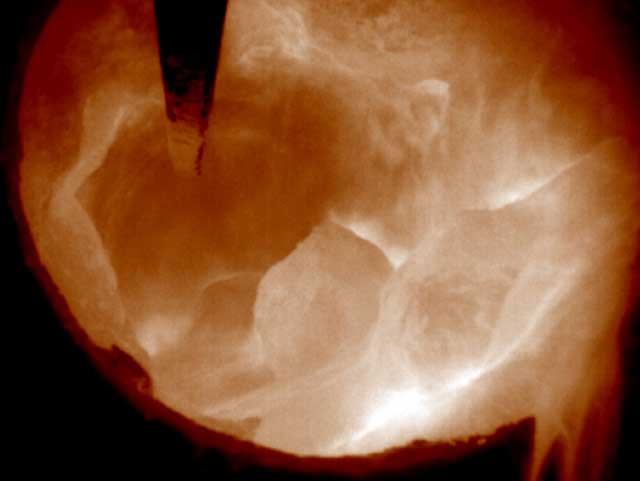

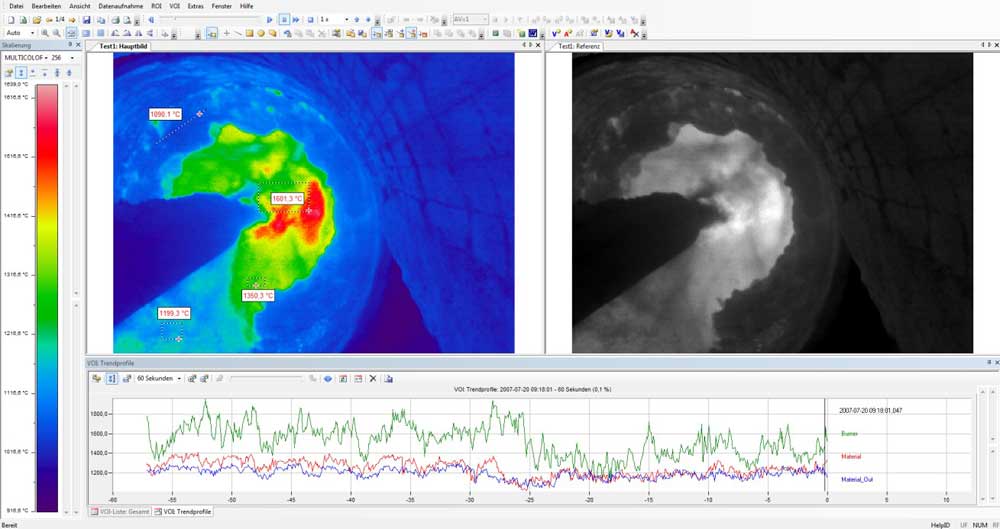

The PYROINC cameras for combustion chambers are special and very robust infrared cameras that are used for the measurement of high temperatures between 400 °C and 1800 °C.The PYROINC cameras have a motorfocus borescope lens with protection window. The camera and the borescope lens are installed in a watercooled stainless steel probe cooling jacket. The camera version PYROINC endoscope have a probe cooling jacket with a very small diameter. They can be cooled with air and water.

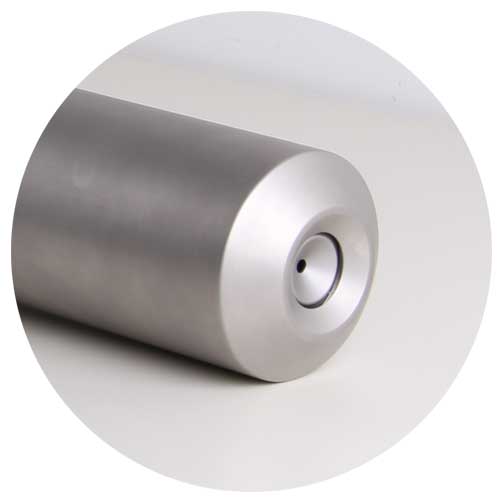

The inlet aperture for the infrared radiation has a patented air purging unit and has a very small diameter. In this way, the probe cooling jacket can be pulled directly through the opening in the combustion chamber walls. Together with the automatic retraction system it is guaranteed that the system withstands the high temperatures and special requirements of the location.

The front part of the probe cooling jacket is able to resist temperatures about 1800 °C with a service life between 2 and 10 years (depending on the operating conditions).

Complete PYROINC system solutions are realized in coorperation with our partner companies CMV Systems and SOBOTTA Sondermaschinenbau.

Advantages of the PYROINC infrared camera for combustion chambers

- One large measuring temperature range

- Industrial continuous operation (service life 2-10 years)

- Automatic retraction system

- Borescope lens with motor focus

- Endoscope versions with small probe diameter

- Special infrared filters for application ranges

- Probe lens jacket with water or air cooling

- Patented air purging system

Type overview: PYROINC infrared cameras for combustion chambers

There are three basic types of infrared cameras available. The datasheets (PDF) with technical data are stored for the respective camera type.

PYROINC thermal imaging cameras for the near infrared range (NIR) “N” (0.8 µm to 1.1 µm)

Areas of application:

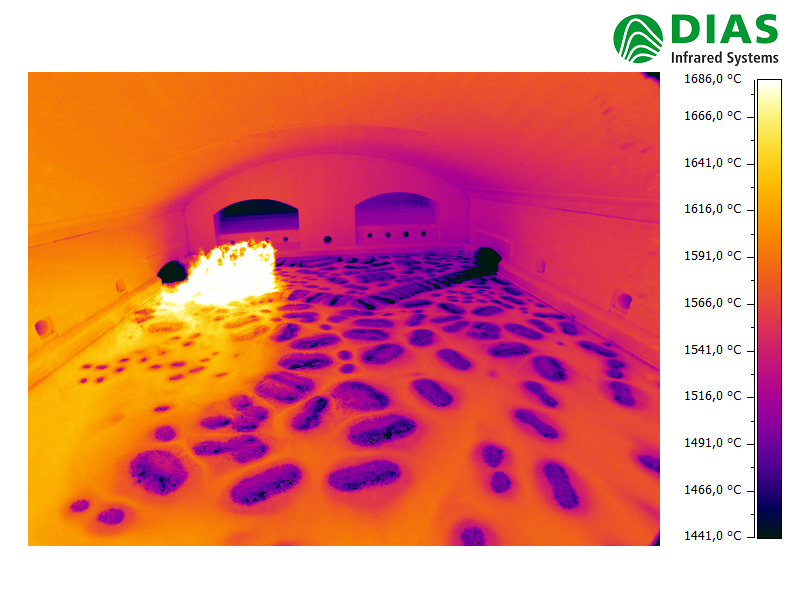

- Temperature measurement of the molten glass and inspection of the lining in glass melting furnaces

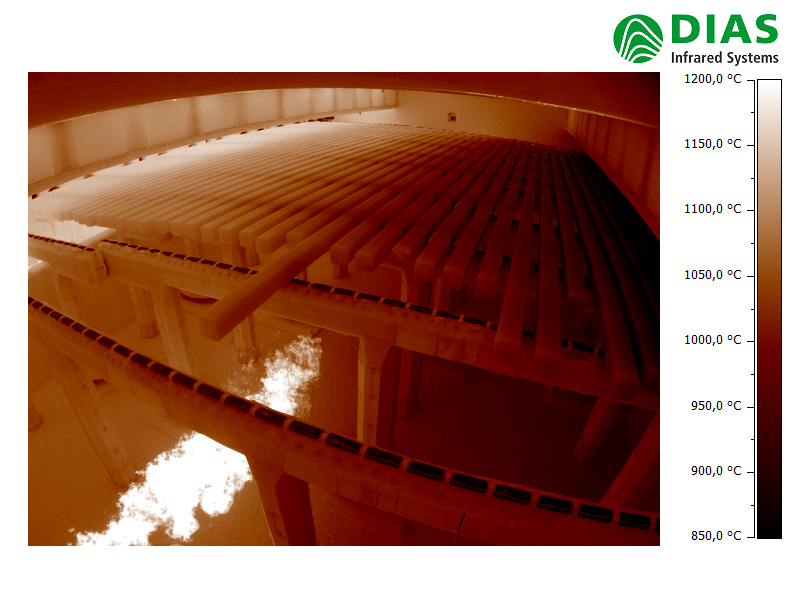

- Controlling the temperature during hardening and tempering of steel in a walking beam furnace

- Online temperature monitoring of the sintering zone in cement rotary kilns

| Camera type | Meausring temperature range | Sensor resolution | Spectral range | Probe diameter |

|---|---|---|---|---|

| PYROINC 1920N endoscope | 650 °C to 900 °C 750 °C to 1100°C 850 °C to 1300 °C 900 °C to 1400 °C 950 °C to 1500 °C 1100 °C to 1800 °C | 1920 x 1080 pixels | 0.8 µm to 0.9 µm | 60.3 mm |

| PYROINC 1600N endoscope | 650 °C to 900 °C 750 °C to 1100°C 850 °C to 1300 °C 900 °C to 1400 °C 950 °C to 1500 °C 1100 °C to 1800 °C | 1600 x 1200 pixels | 0.8 µm to 0.9 µm | 60.3 mm |

| PYROINC 768N endoscope | 800 °C to 1800 °C | 768 x 576 pixels | 0.8 µm to 1.1 µm | 36 mm |

| PYROINC 768N | 600 °C to 1500 °C 800 °C to 1800 °C | 768 x 576 pixels | 0.8 µm to 1.1 µm | 104 mm |

PYROINC thermal imaging cameras for the middle spectral range (MWIR) “F” (around 3,9 µm)

Areas of application:

- Temperature measurement through flames for burner control

- Detection of excessive slag formation in combustion chambers in the chemical industry and in power plants

- Use in recovery boilers in pulp and paper industry

| Camera type | Meausring temperature range | Sensor resolution | Spectral range | Probe diameter |

|---|---|---|---|---|

| PYROINC 640F endoscope | 800 °C to 1600 °C | 640 x 480 pixels | around 3.9 µm | 60.3 mm |

| PYROINC 640F | 600 °C to 1250 °C | 640 x 480 pixels | around 3.9 µm | 104 mm |

| PYROINC 320F endoscope | 800 °C to 1600 °C | 320 x 240 pixels | around 3.9 µm | 60.3 mm |

| PYROINC 320F | 600 °C to 1250 °C | 320 x 240 pixels | around 3.9 µm | 104 mm |

PYROINC thermal imaging cameras for the longwave spectral range (LWIR) “LF” (around 10.6 µm)

Areas of application: Condition monitoring in aluminum and zinc recycling

| Camera type | Meausring temperature range | Sensor resolution | Spectral range | Probe diameter |

|---|---|---|---|---|

| PYROINC 640LF | 400 °C to 1250 °C | 640 x 480 pixels | around 10.6 µm | 104 mm |