PYROVIEW FDS – Early Fire Detection

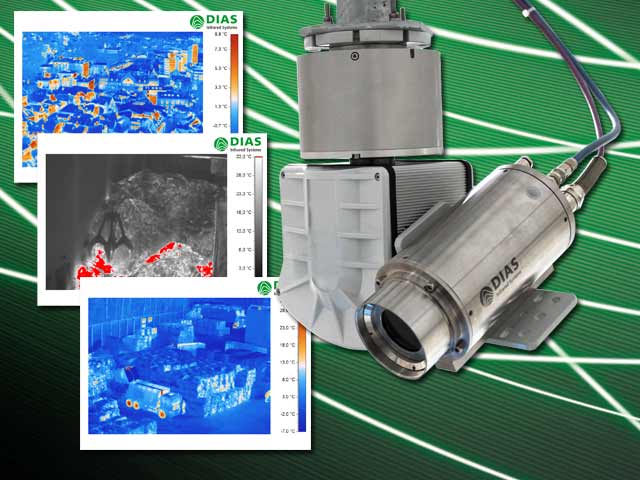

PYROVIEW FDS – Early Fire Detection System with infrared cameras and software

PYROVIEW FDS – That is the proven full automatic DIAS infrared system for the early fire detection. It is used for the detection of hot spots or smoldering fires when paper, waste and combustible materials in closed bunkers and in open areas is stored. Reliable installations for the detection and control of unwanted fires are required here in particular. By spontaneous combustion of the stored materials or by contamination of hot materials fire can develop that bears a high risk for man and environment. Insurance providers recommend therefor the use of infrared cameras for monitoring.

Our infrared camera system PYROVIEW FDS 380L is approved by VdS as infrared camera system for temperature monitoring in fire protection (VdS guideline 3189).

Our infrared camera system PYROVIEW FDS 380L is approved by VdS as infrared camera system for temperature monitoring in fire protection (VdS guideline 3189).

Advantages and features of the DIAS PYROVIEW FDS Fire Detection System

- Modular hardware and software components for customized solutions

- Use in extreme ambient conditions with high dust loading

- Component communication via Ethernet

- Software with flexible client/server architecture

- Seperation of the security-relevant hot spot detection and the operation and visualization

- Software PYROSOFT FDS sends alarm and status information via Email and SMS

- Infrared cameras with diagnostics interface for transpararent remote access

- Further networking with temperature sensors, GPS receivers, weather stations, fire alarm offices and extinguishing system

Possible application of the early fire detection system DIAS PYROVIEW FDS

- Waste bunkers

- Waste incineration plants

- Recycling companies

- Recycling sorting plants

- Used tires plants

- Paper mills

- Wood processing

- Early fire detection in forests

- Early fire detection in street tunnels

Raise an alarm before it starts burning

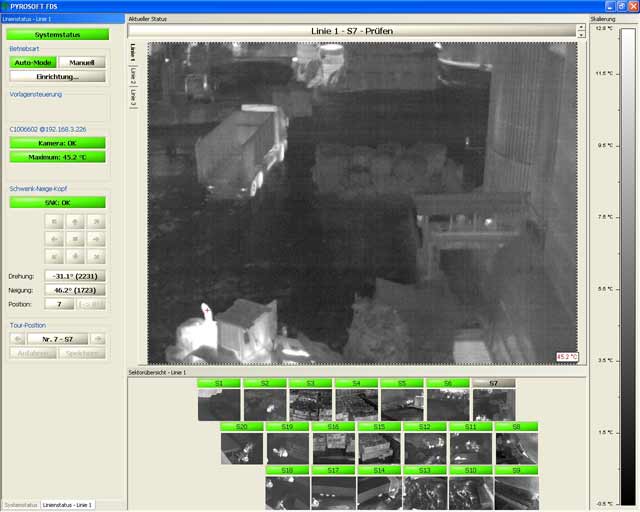

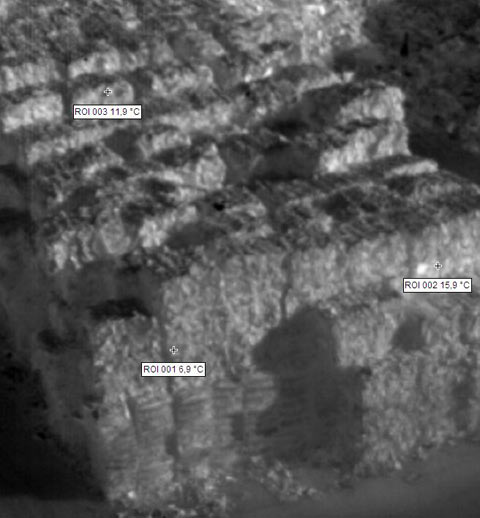

When exceeding preset temperature threshold values in the Regions Of Interest (ROI) of the current thermal image the corresponding thermal imaging software PYROSOFT FDS signalizes the alarm status and files the appropriate measurement data. In the case of a fire areas with temperature exceedances are marked red. In this way the operator can recognize the fire immediately and start fire fighting measures. Alarms and system states can be displayed on a PC monitor and the operator panel of the system that can be connected directly to the coordination center of the fire brigade. Own water cannons can also be integrated into the system solutions and so they can be aimed to the fire.

Easy access via app

PYROSOFT FDS Client is an app for Android and iOS that provides online access to PYROVIEW FDS systems for early fire detection. It is available for download from the Google Play Store and the Apple Store. All devices from Android 6.0 and iOS 10.0 are compatible. Prerequisite for the use of the app is a network connection to the PYROVIEW FDS server. Thus, image data as well as status information can be accessed at any time and commands for remote control can be transmitted. In the event of an error or alarm, a notification is sent by push message or email so that a quick reaction is possible. By looking at relevant information, the situation can be assessed in advance.

More information:

Components of the early fire detection system

The basic element of our IR system is at least one PYROVIEW infrared camera on a pan-tilt-head. Alternatively, the infrared camera can be equipped with an extreme wide-angle lens including a software module for image restitution. Freely definable sectors of the area to be monitored can be selected automatically with the infrared camera. The IR camera measures continuously the temperature distribution on different positions. Here is an overview of the components of the early fire detection system:

- Infrared camera PYROVIEW 380L or 640L

- Weather-proof housing

- Pan-tilt-head

- Reference radiator

- Power supply/USV

- I/O system

- Touch-PC

- Thermal imaging software PYROSOFT FDS and smartphone app PYROVIEW FDS Client

| Modular compononents of the early fire detection system | |

|---|---|

| Infrared camera PYROVIEW 380L or 640L | – Temperature range from –20 °C to 350 °C (optional up to 500 °C) – Spectral range 8 µm to 14 µm – 384 x 288 pixels (380L) or 640 x 480 pixels (640L) – Maximum image frecuency 50 Hz, Ethernet interface |

| Standard housing | – Industry protection housing “Protection FDS” (IP66) – Stainless steel – With integrated air purge unit to avoid contamination of the lens |

| Weatherproof housing | With heating and hard-coated GE window |

| Pan-tilt head | – Move towards to programmable positions, freely manual positionable – 359° horizontal, 180° vertical, 0.2° resolution |

| Reference radiator | – Control of the camera function and pan-tilt function – Little deviations are corrected, malfunction information when heavily contaminated |

| Power supply/USV | – Optimal: 2 isolated feeds (1x buffered, 1x unbufffered) – Optional: own USV for 4 h or 30 h operation |

| I/O system (programmable bus controller) | – Monitoring system status – transmission to PC – Alarming via digital output and further interfaces |

| Touch-PC | – Operation and monitoring station with 21″ touch display |

| Software PYROSOFT FDS | – Server/Client software for easy operation of the early fire detection system |

| App for Android and iOS smartphones | |

Detailed product broschure about PYROVIEW FDS – system for early fire detection

Find our new and very detailed product broschure about our infrared early fire detection system PYROVIEW FDS here: