Infrared cameras and infrared systems for industry thermography

IR camera series PYROVIEW made by German specialist DIAS Infrared

For more than 25 years, DIAS Infrared is a manufacturer and specialist for fixed and portable infrared cameras for non-contact temperature measurement in industry, research and development. You encounter a team of first-class engineers, scientists and technicians with longtime experience in the field of infrared temperature measurement in our headquarter in Dresden (Germany).

We develop and manufacture our infrared camera series in Germany. A good counseling to our thermal imaging cameras as well as an excellent customer service before and after the purchase have top priority. Trust the manufacturer with the worldwide largest product range of fixed infrared cameras and infrared measurement devices.

The advantages of fixed PYROVIEW infrared camera for industrial thermography

- Every infrared camera model is specifically adjusted to the material and the temperature measurement range

- High-quality infrared cameras – developed and manufactured in Germany

- Precise non-contact temperature measurement in the range from –20 °C to 3000 °C

- Adapted wavelength ranges in LWIR, MWIR or NIR spectral range

- Infrared camera models with different thermal image resolutions:

320x 240 pixels to 768 x 576 pixels - Thermal images can be displayed with the free thermography software PYROSOFT compact in real-time with up to 100 Hz

- Further extensive thermography software packages like PYROSOFT Professional and PYROSOFT Automation

- IR cameras can be accessed via web browser: Web interface with status and image bar for service and maintenance

- Advantages over competitors: Large continuous temperature measurement ranges for high-temperatures and temperature measurement in near infrared range (NIR)

- Two standard variants: PYROVIEW compact+ for universal application and PYROVIEW protection for rough industry environments

- Infrared cameras with Ethernet interface instead of USB connection for the bridging of great distances

- GigE VisionTM compatible

- Galvanically isolated digital inputs (trigger) and outputs (alarm)

- Stand-alone operation without PC connection possible

- No moving outer parts at the housing of the IR camera

- Numerous infrared lenses with motor focus

- Use of uncooled infrared sensors

- Specifically suitable for industrial continuous operation

Your contact to us:

Phone.: +49 351 896 74-0

Email: sales@dias-infrared.com

Do you have questions?

Use our contact form!

Describe your measurement problem – we solve it together!

PYROVIEW compact+ – Low priced first-time user infrared cameras up to high-end IR cameras

- Different models from first-time user infrared cameras to the professional IR camera for high-end application

- Application specific spectral ranges (LWIR, MWIR and NIR)

- Infrared cameras of low size

- Compact housing made of aluminum with protection class IP54

PYROVIEW protection – infrared cameras for extreme operating temperatures in industrial environments

- Applicable without any problems up to 150 °C operating temperature

- Infrared camera in robust industry protection housing made of stainless steel IP65

- Water cooling, air purge unit and protection window provide an optimum protection of the IR camera in rough environmental conditions (e.g. in production process of glass or steel)

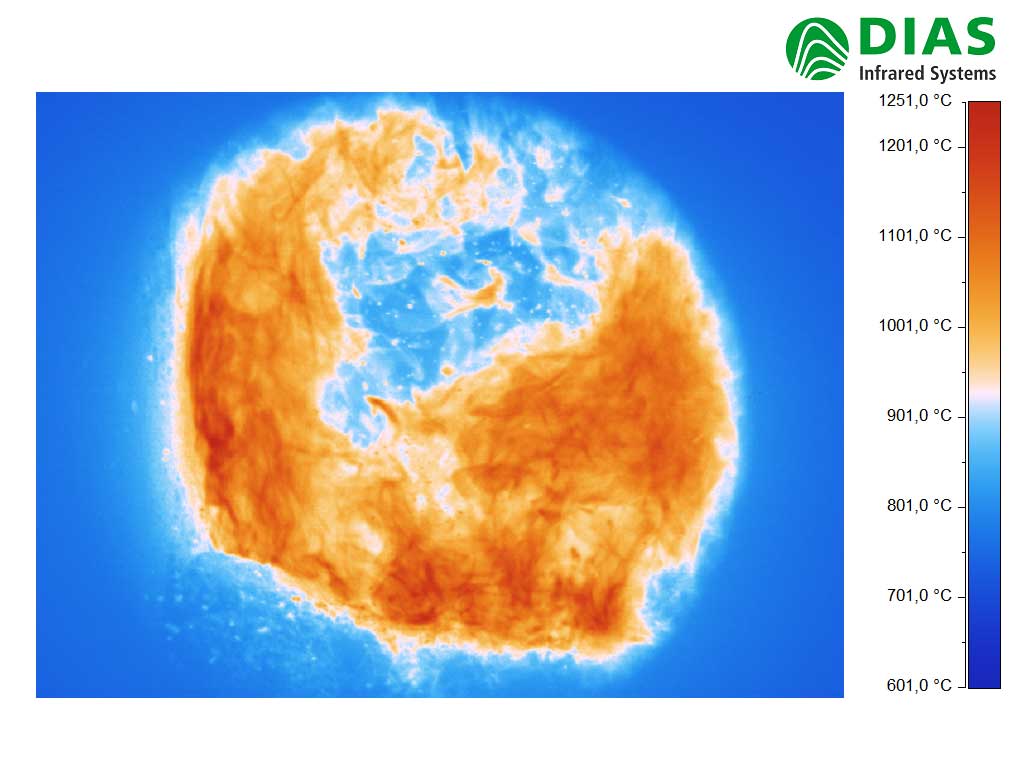

- Infrared camera variants with borescope lenses for combustion chamber application

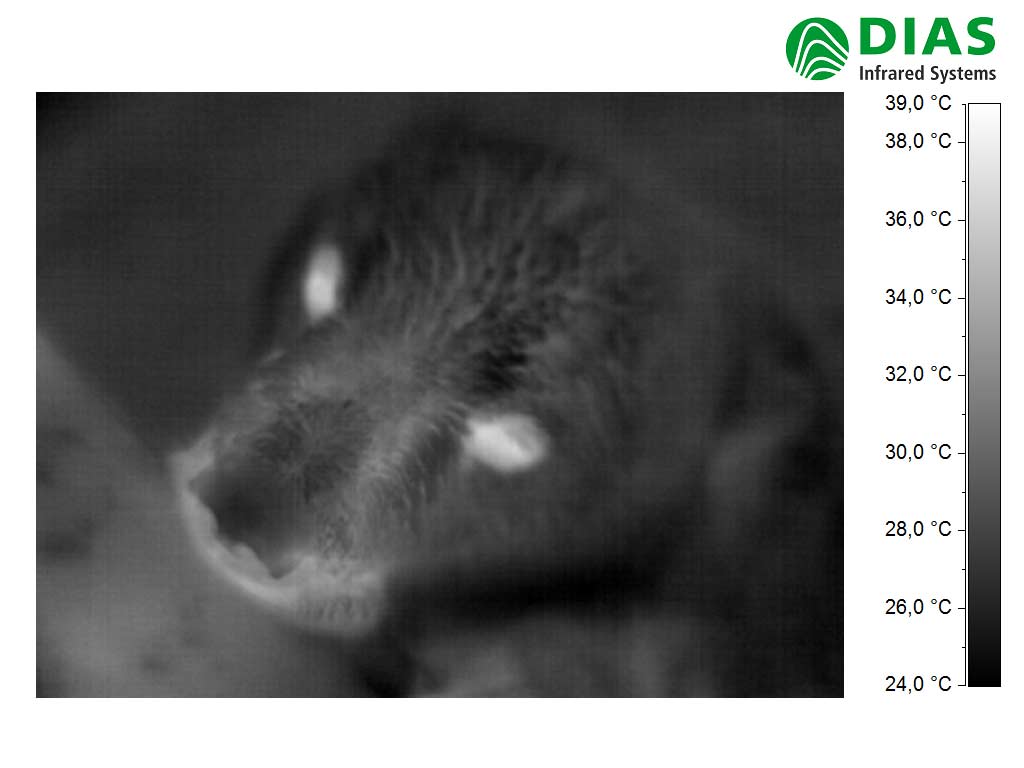

Portable infrared cameras for mobile thermography

For thermography application like building inspection, maintenance, energy production or also industry thermography portable infrared cameras in the standard spectral range from 8 µm to 14 µm are suitable. Our thermal imaging camera PYROVIEW M380L portable is an example:

- Measuring temperature ranges from –20 °C to 550 °C

- Easy to use for fast and efficient work

- Very good image quality: 384 x 288 pixels

- Saving of images and sequences

Together with our partner Testo we provide a selection of further thermal imaging cameras.

Temperatures of versatile materials can be measured with our PYROVIEW infrared camera

The PYROVIEW infrared camera can measure contactless temperatures in the range from –20 °C to 3000 °C and create thermal images. Here is an overview:

| Material | Temperature range | Spectral range | Example |

|---|---|---|---|

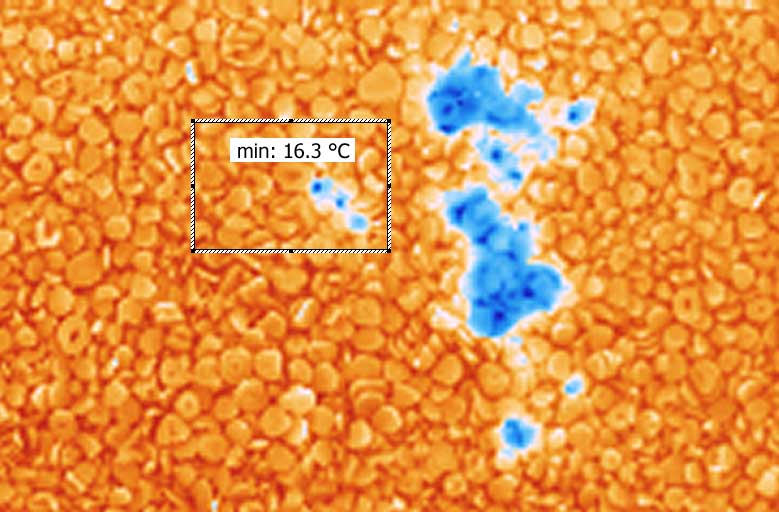

| Non-metals (e.g. groceries, plastic, wood, paint-coated surfaces) | –20 °C to 500 °C | 8 µm to 14 µm (LWIR) | Temperature measurement on freeze-dried fruits or baked goods |

| Glas surfaces | 200 °C to 1250 °C | 4.8 µm to 5.2 µm (MWIR) | Inspection of cooling process of float glass production |

| Temperature measurement through flames | 600 °C to 1250 °C | around 3.9 µm (MWIR) | Temperature measurement in incineration plants |

| Ceramic, metal | 100 °C to 500 °C | 3.0 µm to 5.0 µm (MWIR) | Monitoring of soldering process in electronics manufacturing |

| Metal, ceramic, graphite | 300 °C to 1200 °C | 1.4 µm to 1.6 µm (NIR) | Process control during hardening of iron and other metals |

| Metal, glass melts | 600 °C to 3000 °C | 0.8 µm to 1.1 µm (NIR) | Quality control during continuous casting manufacturing |

Find the suitable DIAS PYROVIEW IR camera model

Read in our application reports information about the non-contact measurement of temperatures on many different materials like steel, iron and glass in different technological processes (forging, hardening, welding, casting, forming and more).

What is an infrared camera?

An infrared camera is a temperature measurement device that measures the surface temperature of an object without contact. They are many designations for the term “infrared camera”: thermography camera, thermo camera, forward looking device and many more. All terms describe an imaging device that receives infrared radiation. This radiation is the inherent radiation of the measured object, which is emitted in accordance with PLANCK’s radiation law and emissivity. Infrared cameras use often the spectral ranges between 8 µm and 14 µm (long-wave infrared range LWIR). In addition to this standard wavelength range, DIAS Infrared also offers the spectral ranges from 3 µm to 5 µm (mid infrared MWIR) as well as 1.4 µm to 1.6 µm and 0.8 µm to 1.1 µm (near infrared NIR). These wavelength ranges are suitable for non-contact temperature measurement on glass, metals, graphite and ceramics in the high-temperature range from 100 °C up to 3000 °C. To reduce emissivity-related temperature measurement errors, measurements should in principle be made as short wavelengths as possible and/or at wavelengths of high emission.

And how does an infrared camera work?

In principle, infrared cameras are built like an ordinary optoelectronic digital camera. They have an optics, a radiation sensor and an electronic signal processing with data transmission and/or image display. The sensor and the optics of infrared cameras have to be applicable in the requested infrared wavelength range (LWIR, MWIR, NIR). The thermal images that can be displayed via thermography software on a computer or on a display of a portable camera are available as gray scales as temperature/intensity information. Though shades of gray can be differed hardly by the human eye infrared images are displayed often in so-called pseudo-colors. DIAS uses as infrared sensors for their infrared cameras modern uncooled 2D array detectors on the basis of micro bolometers (LWIR and MWIR) as well as Si and InGaAs photodiodes (NIR).

How do I buy the right thermal imaging camera?

When selecting and buying a thermal imaging camera, not only the desired measuring temperature range and price are important, but also a number of other characteristics must be considered. You will find help in selecting a suitable infrared camera in our white paper “How to find the right thermal imaging camera”.